Table of contents

1. What you need to know about the PE jaw crusher.

2. The process of crushing the boulder.

3. Application and properties of jaw crushers.

1.What you need to know about the PE jaw crusher.

|

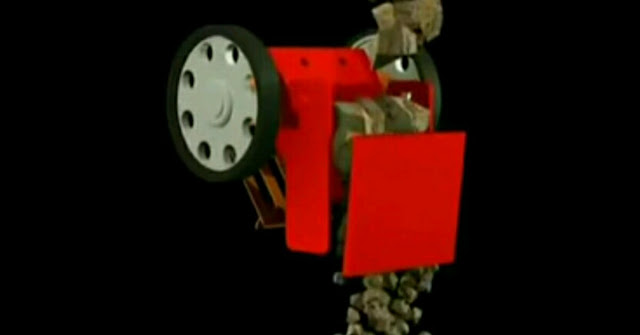

| The principle of jaw crusher is simple |

The PE jaw crusher is based on a revolutionary, non-welded and modular chassis design that provides owners and customers the highest levels of fatigue resistance while providing excellent reliability and multiple mounting options for the machine. Use in many industries. Due to its finely balanced structure, this industrial machine can be one of the simplest and most economical types of crushers that can be actively installed and used. In combination with the high-quality cast steel components and the long-term wear of the parts, this means an extraordinarily high availability of the crusher, a very economical crushing and a surprisingly low price per tonne. In summary, the PE jaw crusher has a simple structure that allows for easy maintenance, stable performance, and even end particles with a high freeness.

The motor of the PE jaw crusher drives the pulley effectively and makes the jaw move up and down about its axis. Once the movable jaw is lowered, the angle between the fixed jaw and the movable jaw begins to decrease, allowing the materials to be shredded and the purpose of grinding to be achieved. The moment the movable claw is raised, it fixes the claw under the draw bar and its spring. After this point, the shredded materials are released from the bottom outlet of the grinding chamber.

Nowadays it is very easy to get a PE jaw crusher, easy to connect and search for suppliers. Every good supplier has its own website, where you can get more information about its products and what they hope to be destroyed. They can also advise you which machine is best for your job. In general, suppliers are experts in their field and therefore have the latest industry information to guarantee you the right product. Each manufacturer must have an "About" section that gives you an overview of his experience.

2. The process of crushing the boulder.

|

| One example of using a jaw crusher |

Boulder crushers are assembled in a factory that performs all the necessary processes to obtain the latest usable end products. However, stone breakers can be mobile so they are transported to the places where these resources were found. The problem with these mobile breakers is that they can only be used to a limited extent and that the resources are used up as soon as the resources are used up.

Step by step grinding process

· The first step is the first breaking step, when large stones are attracted to the first jaw crusher. It is mainly large and has a higher grinding performance. Giant pieces of stone are reduced to smaller stones, which are transported by a vibrating feed machine to the next stage.

· The second phase is called secondary shredding. Cone crushers are often used in this phase, where stone, fine gravel and sand are ground stronger.

· The next step is to use a vibrating screen that separates the different gravel sizes. Only those who meet the required size will move on to the next step, those that are even more voluminous will be restored through the crushing process.

3. Application and properties of jaw crushers.

A jaw crusher is basically a machine that crushes building materials like rocks into small pieces. This helps to break large rocks into smaller pieces, eg. As gravel, to crush. These machines are very useful as they divide the rocks into uniform sizes. There are different types of crushers that are used for different purposes. The two basic machine types include the double lever and the top eccentric. Different types of crushers use different methods of crushing stones.

These machines are generally used in construction sites and quarries for crushing stone. Large stones and stones must be broken up into smaller pieces for easy transportation. The machine has two rigid metal parts and an opening with a funnel. The stones or stones are poured into the funnel and crushed by the two metal parts by compression. One of the pieces is fixed between the two base metal pieces and the other moves in the direction of crushing the stones.

Each mill has a specific feed size that actually indicates the size of the object that can crush the machine into pieces. It is very important to consider the power capacity of these devices as different industries have different specifications and requirements. The specification is based on the distance between the two metal parts that perform the grinding task.

The specification of the opening of the delivery also varies from company to company. Some manufacturers produce these machines with specific measures to open the charger.

The capacity of the jaw crushers also varies. The capacity of the machine indicates the total weight of the material that can process a unit in one hour. This information may vary from manufacturer to manufacturer.

The reduction ratio is another important factor to consider when purchasing these crushers. There must be a perfect balance between the amount of material poured into the machine and the space of the grinding surface.

Jaw crushers are often used for various applications. It is used in the construction and demolition area, as it is the size of large materials such as concrete, stones, etc. reduced. Therefore, it is very effective to remove deposits from the construction site.

It is also used to easily crush pebbles and granite stones. The stones are broken into uniform sizes to simplify the construction process.

These crushers are also used as an important accessory for better production because they consume less energy.

These machines are ideal for crushing hard materials and stones such as quartz, iron, copper and other materials. These materials are stretchy and can rarely be crushed with other equipment.

You can purchase various types of crushing tools at competitive prices in online stores. Since there are a large number of these machines in online shops, it is easy to select devices according to specific needs.

No comments:

Post a Comment