Table of content

1. Hystory.

2. Where else is contained?.

3.Metal properties.

4.The use of manganese in the metallurgical industry.

5.Categories of manganese ore deposits.

1. Hystory.

|

| Mangan has a long history |

Manganese is a gray metal with a steel sheen that has a high hardness value. The extraction of manganese ore is of great importance, because it is used in almost all industries. The story of the appearance of Manganese can not be found in nature in its pure form. The main mineral in which it is contained is called pyrolusite. In ancient times it was used as a glass clarifier during cooking, as well as for dyeing fabrics. At the end of the 18th century, the Swedish chemists K. Scheele and Y. Gan discovered that the ore contained a metal in appearance resembling iron. He received the name "manganum", which was later transformed into "manganese".

2. Where else is contained.

|

| Various uses of manganese |

- Its deficiency adversely affects the work of all human organs and systems.

- It is difficult to overestimate the importance of manganese, because it:

- Strengthens the nervous and cardiovascular systems;

- Normalizes the activity of the thyroid gland;

- Positive effect on reproductive function; regulates blood sugar levels;

- Speeds up the metabolism; maintains the necessary level of cholesterol in the blood;

- Strengthens the immune system.

3. Metal properties.

|

| Manganese can be used with alloys with other metals |

The electronic formula of manganese: [Ar] 3d5 4s2. Formula of manganese in pyrolusite: MnO2xH2O. The widespread use of manganese due to its high chemical activity - it is able to react with a large number of elements, forming alloys. It also interacts well with oxygen, carbon, nitrogen and other non-metals. Being in a vacuum, the metal, when heated, is able to evaporate from any alloy, it dissolves in acids, reacts with water.

4. The use of manganese in the metallurgical industry.

|

| Industrial use of manganese |

The solution has no contraindications, it is allowed even for the care of the umbilical wound of babies. But it is important to remember that a highly concentrated solution can cause severe burns.

Manganese ore mining methods. About 25 million tonnes of manganese ore are mined in the world every year. Work is carried out mainly in the open way, at least - underground. Quarry development is used if manganese ore deposits are not deeply buried underground. Depending on the area of the field, dig pits of various sizes. The development of a quarry is carried out as follows: with the help of special equipment (most often bulldozers), the top layer of the earth is covered and removed, covering the deposits of the fossil; manganese ore is crushed; ore is loaded on dump trucks and sent to the plant for processing. after completion of the work, the quarry is again covered with a layer of earth, and reclamation takes place.

With the underground mining method, the main task is to lift the ore to the surface. The process consists in the following: horizontal (adits) or vertical passages (mines) are dug on the territory of the field; ore crushing is carried out underground with the help of equipment; the ore is loaded onto a conveyor and delivered to the surface. Underground method of extracting manganese ore is more expensive financially than open. It requires more modern equipment and workers. But ore mined under the ground is considered to be of higher quality, the investment pays off when it is sold.

However, with the open mining method, a large number of workers is not required, the equipment is simpler and more economical to use. The main advantages of open development are: high labor productivity; relative process safety (the likelihood of accidents is much less than in underground work). These benefits compensate for the negative impact of weather conditions and the need to cultivate a large area of land.

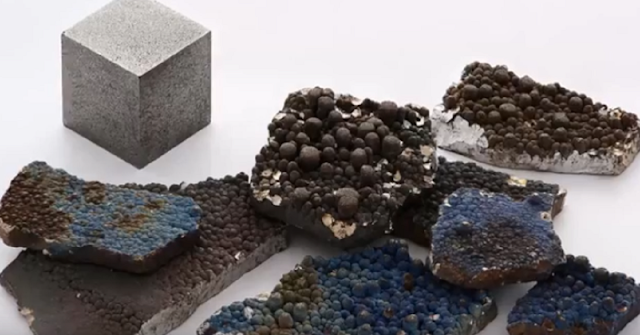

5. Categories of manganese ore deposits.

|

| Manganese ore deposits |

Depending on the complexity of the geological structure, form and size of ore, all deposits are divided into 3 types (established by the relevant order “On the classification of manganese ore reserves” of 11.12.2006): 1st group of difficulty - deposits geological structure; ore is represented by large layers in which manganese is evenly distributed; 2nd group of complexity - deposits with a complex geological structure; ore is represented by large strata in which manganese is unevenly distributed; 3rd group of complexity - deposits with a complex geological structure; The ore is represented by small layers, in which manganese is unevenly distributed, and its amount is extremely small.

Methods for extracting manganese from ore Most often, pure manganese is obtained from the ore by leaching. In the process, various chemical substances can be used, for example, sulfurous acid, ferrous sulfate, ammonium sulfate, etc. Their diversity is due to the fact that manganese has many compounds and modifications, each of which reacts differently in chemical reactions.

Despite the fact that there is no definite classification of methods for extracting metal from manganese ore, they all have a similar process: the ore is crushed to an extent that ensures the maximum reaction rate when interacting with various substances; the leaching process starts, as a result of which manganese takes the form of a solution; the resulting solution is free from impurities; when exposed to a reagent or when it is evaporated, manganese precipitates in pure form. With the help of chemical reagents, manganese can be extracted from sludge, low-grade ore, industrial waste. Where do you get manganese ores?

Lead Countries Today, the leader in the production of manganese ores is Russia, it has been at the forefront for several decades. In other states there are no explored large and rich deposits, their search is ongoing. The widespread use of manganese in the metallurgical industry has provided him with economic attractiveness. There are small deposits in the following countries: Bulgaria, Romania, China, Ukraine, Kazakhstan, Czech Republic, Germany, South Africa, Brazil, India, Australia, Japan, Indonesia, Mexico. In most of them are concentrated deposits of ore, not characterized by high quality. The needs of these countries are met by imported ore.

Countries with a high level of development of the metallurgical industry (USA, France, Belgium, etc.) are actively searching for large deposits in order to reduce imports. This will allow them to meet the internal needs of the state at the expense of their own resources. -

The increased interest of the United States is aimed at the extraction and further use of iron-manganese ore in the industry, which is concentrated on the bottom of the World Ocean. Mining of manganese ore in Russia Despite its leading position, Russia is experiencing significant problems in the field of manganese mining. The collapse of the Soviet Union was marked by the onset of an extreme degree of high quality metal deficiency. The main part of the work on its production was carried out at the fields, which are now territoriality owned by other states. This situation forced Russia to acquire high-quality manganese in foreign countries at import prices in order to cover the needs of the metallurgical industry. This situation persists to this day.

Industry prospects The metallurgical industry, which is rapidly gaining momentum in development around the world, is forcing countries to actively search for manganese ore deposits. Technologies are being improved every year, prospective areas are being developed. The main goal of any state is to reduce the volume of imports so that the satisfaction of domestic needs takes place mainly at the expense of its own resources.

No comments:

Post a Comment