Cone

23:02

The type of stone crusher you need

Large stones cannot be directly used directly for various purposes. For this reason, a stone crusher is needed so that the stone is small in size so that it can be used immediately.

Table of contents

1.Understand cone crushers

2.Manufacturer of stone crusher

3.Cone crushers that can increase your profitability

Cone crushers are one of the most common types of stone crushers. They are used to reduce the size of large rocks and minerals into smaller pieces and granules. They are used in various industries. such as the mining, metallurgical, constructive and chemical and phosphate industries. They can also be used for social or governmental projects, eg. B. for railway rehabilitation and road construction.

Components

A cone crusher is a very complex machine that consists of many components, but whose main structure is the same, consisting of:

Main axis: is used to assemble the spirit. It is supported by the bearing on the base and fastened under the mantle. The main shaft itself does not rotate, driven by the bevel gears rotated in the opposite axis. In reality, however, it is housed in a rotating environment.

Counter-axle: The counter-shaft generates a rotary movement in the cone crusher. On the outside of the tree is a pulley and inside a pinion. The gearbox drives the housing of the eccentric main shaft.

The feathers: Large springs are part of the safety mechanism in cone crushers, which prevents damage to the course by harder and stronger rocks. Press the upper structure down to prevent hard stones that can not be crushed from moving and damaging the crusher as they enter the cavity.

Manganese mantle: The manganese mantle is one of the grinding surfaces of the machine in question, ie the cone crusher. Make a spherical twist through an eccentric rag, like an ice cream cone machine that fills the material into the cones!

Business

The working principles of the cone crusher are similar to those of rotary crushers with a more parallel zone and less inclination in the crushing chamber. As a result, the rocks are broken by being crushed and crushed between the spindles, turning eccentrically and surrounding the concave funnel. The rotating spring is covered by the wear-resistant sheath and the concave funnels by the lining of the manganese bowl or concavity.

The grinding chamber is the area between the cone and the moving cone. When the stone or ore enters the cone crusher from above, it remains in the upper zone and is compressed between the lining of the bowl and the mantle. The large parts break and they are allowed to fall to the lowest position, where they are broken again. This process lasts until these pieces are small enough to escape through the narrow opening available for these parts in the lower part of the machine, ie the lower zone.

The advantages

Cone crushers are one of the most advanced and efficient types of rock breakers. They offer many advantages, including the high milling content, the thin and even size of the product, the low energy consumption and the good granule products. They consist of ultrathin and energy-efficient rock elements. They use the principle of the sliding cover and cover a wide range of products. Its free space in the cavity is more practical than any other type of crusher machine. The use of high performance rock, shaft diameter and a separate lubrication system ensures the reliability and longevity of the machine.

For example, The United Kingdom has a rich mining history: There are several types of industrial minerals. The most common industrial minerals are sand, gravel and cement, which are used in construction products and in road construction. In the UK, many slate mines produce shale, which is then used for construction and architectural purposes. There are slate mines in England and Scotland, but most are in Wales. In the United Kingdom, there is also a large amount of other minerals, such as Chinese clay, used in fine porcelain and porcelain, especially in the Pottery region of the West Midlands (where most producers are located). fine china) and on earth. Fuller, an absorbing mineral used to absorb spills and cleansers. In Great Britain, stone mining requires state-of-the-art shredding technology and a high-quality crushing plant for quarries. If you want to find a manufacturer of stone breakers in the UK, a simple Google search will help you find them.

In the first phase of grinding: Imagine you have to cut cheese, you can make pieces with a hand, a knife or something else, such as a grater. Imagine, if the meat you want to cut is meat, then a knife is the only option. You really can not cut it to pieces by hand. If the material is hard, you can only use a shredder. To crush stones, you need something like a jaw crusher or an impact crusher from a manufacturer. Theoretically, it's better to work with a model that does not wear out too quickly. Efficiency and reliability are the most important things.

It is clear that a stone crusher is essential for heavy work such as the decomposition of large quantities of rock material and is also a good manufacturer. The device must operate reliably over a long period of time, coping with high workload and productivity. The stones are crushed into the jaws of the machine into smaller pieces, which can then be used for other purposes or as minerals from larger rocks. This is particularly important in the mining process, where mines cause a large amount of waste. The stone-crusher manufacturers focus on these key qualities as they create new equipment and explore new techniques: they observe what their current equipment is used for, and then market new versions on the market that companies can buy. They are the best. Technology available

Either inefficient machines can slow down production, increase downtime, and unduly burden your profitability, whether you're working in construction, highway, or mining. Failure to meet the deadlines can also damage your reputation. You need to use cone crushers that increase your profitability by offering more than promised and faster than expected.

A cone crusher is an important part of your stone or mineral processing process as it grinds the material to the desired dimensions. Since this process is usually secondary in the crushing plant, some processes depend on crushing in a timely manner, so that the entire process chain functions as a smooth, well-oiled machine. Hammer and jaw crushers are other types of crushing systems. But when you need cone crushers, you need a reliable and robust machine that will not leave you at the center of your project.

Nordberg is one of the many well-known companies that makes tough cone crushers. The company manufactures various models of cone crushers through its HP or High Performance range to suit different sectors and requirements, including ballast, sand, taconite, limestone, etc. Nordberg will most certainly be transporting a shredder for transport between different locations ,

The company's mobile crusher can be pulled anywhere, using a closed loop crusher and sifting process with a conveyor belt to quickly shred the bricks in three different designs. The company's machines enable faster shredding due to the patented technology, which allows for faster speed and longer start-up and better performance than the crusher. The particulate release safety system, coupled with a fixed setting that allows for better stability and lower deflection, ensures that castings are easily ejected while maintaining consistency in the production of finished bricks or minerals.

,

The technological features of several Nordberg cone crushers provide benefits in terms of ease of maintenance as all interchangeable parts are easily accessible. Among other benefits, there is less downtime due to its superior ability to eliminate stragglers and very low maintenance costs through the use of superior labyrinth seals, bronze rings, and most parts of each mill are easily interchangeable. These breakers also have a very flexible design. By simply exchanging some key components, you can switch your crusher from the thickest to the thinnest void. All of these features result in greater savings, less downtime, and faster delivery of the required raw material, increasing your ROI and improving your reputation.

You need a company that not only manufactures rugged and energy-efficient crushers, but also provides after-sales service in the event of a problem. A company that is present in many countries and cities should be privileged as it can communicate with you as quickly as possible. Companies like Nordberg can guarantee that their cone crushers perform better than they expect, while the design and performance of these crushers allow for easy maintenance in case of scheduled maintenance or unwanted problems.

Table of contents

1.Understand cone crushers

2.Manufacturer of stone crusher

3.Cone crushers that can increase your profitability

1.Understand cone crushers

Cone crushers are one of the most common types of stone crushers. They are used to reduce the size of large rocks and minerals into smaller pieces and granules. They are used in various industries. such as the mining, metallurgical, constructive and chemical and phosphate industries. They can also be used for social or governmental projects, eg. B. for railway rehabilitation and road construction.

Components

A cone crusher is a very complex machine that consists of many components, but whose main structure is the same, consisting of:

- Main axis

- Against axis

- The feathers

- Manganese

|

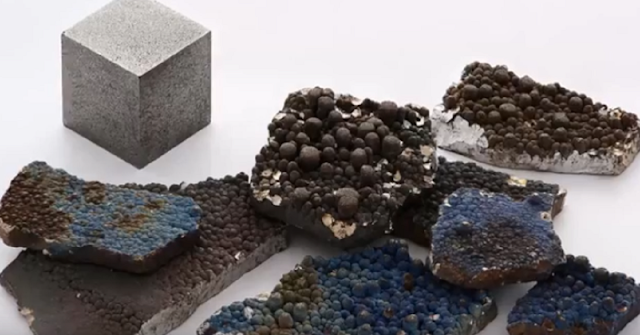

| Stone crusher can simple until complex machine |

Main axis: is used to assemble the spirit. It is supported by the bearing on the base and fastened under the mantle. The main shaft itself does not rotate, driven by the bevel gears rotated in the opposite axis. In reality, however, it is housed in a rotating environment.

Counter-axle: The counter-shaft generates a rotary movement in the cone crusher. On the outside of the tree is a pulley and inside a pinion. The gearbox drives the housing of the eccentric main shaft.

The feathers: Large springs are part of the safety mechanism in cone crushers, which prevents damage to the course by harder and stronger rocks. Press the upper structure down to prevent hard stones that can not be crushed from moving and damaging the crusher as they enter the cavity.

Manganese mantle: The manganese mantle is one of the grinding surfaces of the machine in question, ie the cone crusher. Make a spherical twist through an eccentric rag, like an ice cream cone machine that fills the material into the cones!

Business

The working principles of the cone crusher are similar to those of rotary crushers with a more parallel zone and less inclination in the crushing chamber. As a result, the rocks are broken by being crushed and crushed between the spindles, turning eccentrically and surrounding the concave funnel. The rotating spring is covered by the wear-resistant sheath and the concave funnels by the lining of the manganese bowl or concavity.

The grinding chamber is the area between the cone and the moving cone. When the stone or ore enters the cone crusher from above, it remains in the upper zone and is compressed between the lining of the bowl and the mantle. The large parts break and they are allowed to fall to the lowest position, where they are broken again. This process lasts until these pieces are small enough to escape through the narrow opening available for these parts in the lower part of the machine, ie the lower zone.

The advantages

Cone crushers are one of the most advanced and efficient types of rock breakers. They offer many advantages, including the high milling content, the thin and even size of the product, the low energy consumption and the good granule products. They consist of ultrathin and energy-efficient rock elements. They use the principle of the sliding cover and cover a wide range of products. Its free space in the cavity is more practical than any other type of crusher machine. The use of high performance rock, shaft diameter and a separate lubrication system ensures the reliability and longevity of the machine.

2.Manufacturer of stone crushers

For example, The United Kingdom has a rich mining history: There are several types of industrial minerals. The most common industrial minerals are sand, gravel and cement, which are used in construction products and in road construction. In the UK, many slate mines produce shale, which is then used for construction and architectural purposes. There are slate mines in England and Scotland, but most are in Wales. In the United Kingdom, there is also a large amount of other minerals, such as Chinese clay, used in fine porcelain and porcelain, especially in the Pottery region of the West Midlands (where most producers are located). fine china) and on earth. Fuller, an absorbing mineral used to absorb spills and cleansers. In Great Britain, stone mining requires state-of-the-art shredding technology and a high-quality crushing plant for quarries. If you want to find a manufacturer of stone breakers in the UK, a simple Google search will help you find them.

|

| Stone crusher serves to break the stone up to a small size so that it can be used |

In the first phase of grinding: Imagine you have to cut cheese, you can make pieces with a hand, a knife or something else, such as a grater. Imagine, if the meat you want to cut is meat, then a knife is the only option. You really can not cut it to pieces by hand. If the material is hard, you can only use a shredder. To crush stones, you need something like a jaw crusher or an impact crusher from a manufacturer. Theoretically, it's better to work with a model that does not wear out too quickly. Efficiency and reliability are the most important things.

It is clear that a stone crusher is essential for heavy work such as the decomposition of large quantities of rock material and is also a good manufacturer. The device must operate reliably over a long period of time, coping with high workload and productivity. The stones are crushed into the jaws of the machine into smaller pieces, which can then be used for other purposes or as minerals from larger rocks. This is particularly important in the mining process, where mines cause a large amount of waste. The stone-crusher manufacturers focus on these key qualities as they create new equipment and explore new techniques: they observe what their current equipment is used for, and then market new versions on the market that companies can buy. They are the best. Technology available

3. Cone crushers that can increase your profitability

Either inefficient machines can slow down production, increase downtime, and unduly burden your profitability, whether you're working in construction, highway, or mining. Failure to meet the deadlines can also damage your reputation. You need to use cone crushers that increase your profitability by offering more than promised and faster than expected.

A cone crusher is an important part of your stone or mineral processing process as it grinds the material to the desired dimensions. Since this process is usually secondary in the crushing plant, some processes depend on crushing in a timely manner, so that the entire process chain functions as a smooth, well-oiled machine. Hammer and jaw crushers are other types of crushing systems. But when you need cone crushers, you need a reliable and robust machine that will not leave you at the center of your project.

Nordberg is one of the many well-known companies that makes tough cone crushers. The company manufactures various models of cone crushers through its HP or High Performance range to suit different sectors and requirements, including ballast, sand, taconite, limestone, etc. Nordberg will most certainly be transporting a shredder for transport between different locations ,

The company's mobile crusher can be pulled anywhere, using a closed loop crusher and sifting process with a conveyor belt to quickly shred the bricks in three different designs. The company's machines enable faster shredding due to the patented technology, which allows for faster speed and longer start-up and better performance than the crusher. The particulate release safety system, coupled with a fixed setting that allows for better stability and lower deflection, ensures that castings are easily ejected while maintaining consistency in the production of finished bricks or minerals.

,

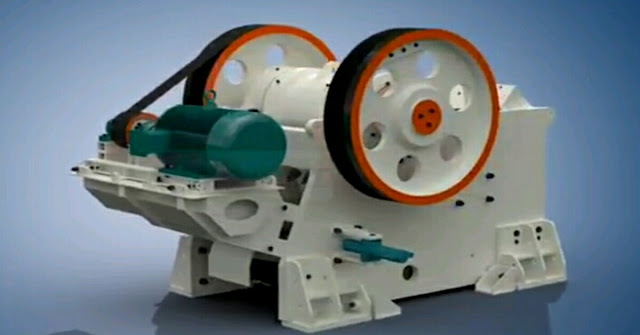

|

| How the stone crusher works to break rocks |

You need a company that not only manufactures rugged and energy-efficient crushers, but also provides after-sales service in the event of a problem. A company that is present in many countries and cities should be privileged as it can communicate with you as quickly as possible. Companies like Nordberg can guarantee that their cone crushers perform better than they expect, while the design and performance of these crushers allow for easy maintenance in case of scheduled maintenance or unwanted problems.