2. Lead ore treatment.

3. Portable Quarrying Plant.

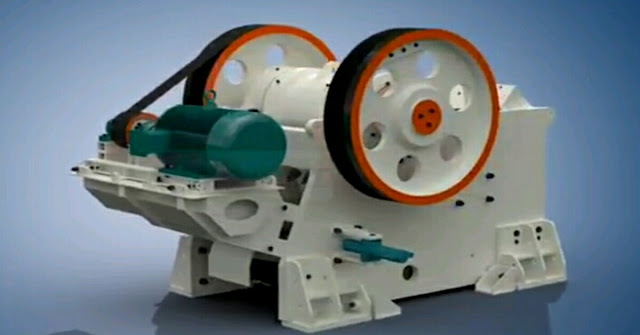

1.Equipment for the treatment of lead or ore

|

| Cone Stone crusher is suitable for processing lead |

Lead is rarely used in its pure form as minor alloying additions greatly increase its strength. For applications where higher strengths are required, compounds such as lead-coated steel can be used.

The very high lead density lends itself to very different applications, such as sound, vibration and radiation protection as protection for users of computer screens and televisions. For this purpose, lead is used in metallic form or as a lead compound in lead glasses.

Some lead compounds have their own useful properties, especially in terms of color and the ability to form glass. As we can see, there is a potential market for lead ore in the future. The processing of lead ore is becoming more important.

2. Lead ore treatment.

|

| One of the tin processing industries |

The hydraulic cone crusher offers a better milling frequency and an eccentric distance, allowing a larger proportion of fine particles to be produced. And particles whose release is less than the closed line can reach 80%, which can significantly improve next processing capacity and reduce overall consumption. Now the hydraulic cone crusher has become the latest production to replace the spring cone crusher and the normal hydraulic cone crusher, and has also become the ideal equipment for large stone materials and crushing pits.

The HCS series hydraulic cone crusher uses computer optimization design to accelerate main shaft speed. The exclusive material exchange system of the baking plate makes it possible to quickly replace the components of the grinding chamber to meet the requirements of different sizes. The construction of the friction disc and the rotation of the eccentric shaft around the fixed cone, as well as the more meaningful "labyrinth seal" system, are the unique features of the HCS series, which offer more advantages as a function Simple, wider range of use, reliable and smooth operation compared to the spring cone crusher and conventional. It is the ideal equipment for the large rock quarry and mining.

Manual hydraulic cone crusher

1, large reduction ratio, high production efficiency;

2, reducing the consumption of wearing parts, reducing operating costs;

3, broken pyramid, perfect shape of the product;

4, hydraulic protection and hydraulic pressure cavity, high degree of automation to reduce downtime;

5, rare, reliable and advanced lubricant products to improve life.

3. Portable Quarrying Plant

|

| Lead processing can also use portable machines |

The rock crushing plant offers you a complete solution for equipment and services. We provide comprehensive technical support in the planning, installation, testing and training of personnel. The entire line consists of stone crushers for sale, impact crushers, vibration conveyors, vibrating screen, conveyor belt, electrical control system. Depending on the specific requirements, we can combine different models to meet different requirements.

Operation and properties.

First of all, the raw materials are regularly transported from the vibratory conveyor to the elementary grinding machine, after which the elementary products are transferred from the belt conveyor to the impact mill for secondary payment. The secondary products are separated by the vibrating screen according to their size. Products that do not meet the requirements are returned to the impact mill for further grinding.

The entire production line is highly automated and the finished product sizes are uniform, well-adjusted and can be adjusted with a high milling ratio, high processing capacity and low energy consumption. They are suitable for all types of products. Crushing station for the construction of roads and bridges.

The river of the stone grinding plant.

First, the raw materials are sent through the hopper in the vibratory conveyor, they are promoted uniformly and continuously in the jaw crusher. After being crushed by the jaw crusher, the materials are sent to the stone crusher, where they are produced by secondary shredding, creating a cubically shaped product. After the second crushing, the materials are sent to a vibrating screen, which separates the various products according to your needs. Although these particles have not reached the required fineness, they are returned to the impact mill for tertiary staking. Depending on the various technical requirements, use a suitable device model, research the article and develop the optimal behavior.

No comments:

Post a Comment