The most important raw materials for cement production are limestone, clay, sand, shale and iron ore. Limestone is usually extracted from the site, while other by-products from the site or nearby quarries can be recovered. Industrial by-products are another source of raw materials. The use of derived materials as a substitute for natural resources is a key element for sustainable development.

Content

1. History of Concrete and Its Ingredients.

2. Do you have too few options.

1. History of Concrete and Its Ingredients.

To understand the history of the concrete, we must first understand what the concrete is and how it is composed. Concrete is a building material that consists of cement, coarse aggregates, sand and water. The chemical process, known as hydration, solidifies the concrete after it has been laid, making it a very versatile and durable building material. Cement, the main constituent of concrete, is chemically composed of calcium, silicon, aluminum and iron. The materials commonly used in cement production are limestone, sand and clay, which contain all the chemicals needed to produce cement.

|

| Cement consists of various components |

Concrete was invented in 1243 for the first time by the Romans. It is not clear in what form or from which components Roman cement is made. However, Assyrians and Babylonians used clay as a binder or cement in their concrete. In 1756, British engineer John Smeaton invented what we now call modern concrete. Smeatons concrete consisted of small stones as aggregates and activated bricks as a cement additive. The English inventor Joseph Aspdin invented Portland cement in 1824, the cement that dominates cement production to this day.

Concrete has existed since the Roman Empire, but not in its form, but since the birth of modern civilization. It has proven to be a reliable and versatile building material and is almost indestructible in the reinforced state. The United States has a specific industry of $ 35 billion a year, employing about two million workers in the United States alone. Concrete is not only a solid building material, it has also helped to build our economy and continues to grow. Concrete will occupy an important place in the construction industry in the coming years.

2. Do you have too few options?

|

| It is necessary to ensure high levels of cement in nature |

In the first phase (2005-2007), the cement sector has far exceeded the ETS emission limits. However, as we approach Phase II (2008-2012) of the emissions trading scheme, there is increasing concern that reduction options will become increasingly constrained and more costly. The industry is concerned that the pressures exerted by the current EU ETS structure will result in exports of production and hence emissions beyond the EU's borders. In her view, her arguments are important for a new approach to emissions control in this sector.

To assess the impact of the EU Emissions Trading Scheme on the European cement industry, The Strategy Works conducted in-person interviews with key figures from the five major global players: Lafarge, Holcim, Heidelberg, Cemex and Italcementi. as well as a telephone interview. with Cembureau, the European professional association of industry.

The total turnover of these five companies in Europe is estimated at 26,000 million euros in 2006. Lafarge is a leader in the European cement market, with Holcim and Cemex competing for second place. , Together, these three companies account for around 70% of the turnover of the five companies surveyed.

The demand for cement in Europe is steadily rising by 2 to 3% per year. It is proportional to economic growth, and Lafarge points out that emerging economies today account for up to 80% of global demand, a trend that is expected to increase and change the global landscape of the sector. Industry efforts to reduce emissions are already ahead of the introduction of the EU Emissions Trading Scheme. Lafarge said it was the first cement producer in the world to set medium-term CO2 emissions targets in 2001. Other companies have done likewise. The five companies surveyed now have medium-term targets (2010-2015) for CO2 emissions. Public domain information, published in its corporate reports and annual reports on sustainable development, confirms that four of the five companies are reducing their emissions according to their goals.

|

| The need for cement continues to increase |

However, the introduction of the EU Emissions Trading Scheme requires mandatory limits for emissions from the sector. Under the EU Emissions Trading Scheme, national governments issue CO2 emission allowances (EUAs) based on emissions reported in recent years, a process known as "big" - fathers. "If they spend more than their allocation, they have to buy European units of account on the open market, and if they expect less, they can sell the surplus.

In the industry, Phase I generally saw generous allocations in Eastern Europe, but strict in the West, which is "not a fair field," according to Holcim. In general, companies were assigned orders for their expected Phase I emissions.

The companies were able to transfer their allocations between countries without having to trade in the open market. Three of the five companies seem to balance their allocation globally or net. Heidelberg "makes it country by country, because CO2 has the same value in all countries"

For its part, Cemex will take into account trade between institutions or countries in the second phase.

Cembureau reports that Phase I was "as usual" in the industry. There is no indication that the system has been shut down, but some factories have reduced or even stopped production due to the EU Emissions Trading Scheme. However, it is to be feared that the allocations for Phase II will be much stricter from 2008 onwards. In that case, the system could indeed cap production, as it may become uneconomic for European industry to buy the additional allowances needed to produce (and thus emit) more than the allotment.

There are several approaches to reducing emissions associated with cement production, but at least in Europe, two are essential. The first is to reduce the amount of clinker in the finished cement, which is referred to as "clinker factor reduction" or material replacement.

|

| Cement is processed as needed, especially in size |

There are two main alternatives for clinker: blast furnace slag and powdered fuel ash (PVA or fly ash). Slag is a non-metallic byproduct of the steelmaking process, whereas PVA is waste that results when the combustion gases of a coal power plant are "cleaned up", effectively removing carbon dioxide means harmful gases.

The second method of reducing emissions is to use alternative fuels, including organic waste, feed and biomass. The savings in emissions are due to the fact that these fuels are considered to be "carbon neutral"; In net terms, they do not emit CO2 throughout their life cycle.

This leads to two economies. Firstly, CO2 emissions per unit of energy content are lower than for conventional fossil fuels, and secondly, indirect savings are associated with the recovery of this waste. If they were not used in the cement kiln, they would be buried or incinerated, which would lead to CO2 emissions to the atmosphere (although the EU Emissions Trading Scheme does not provide loans to avoid these emissions).

Substitution of materials is by far the most effective way to reduce cement emissions. In fact, about 60% of the emissions are emitted by the chemical processes in the furnace, the remaining 40% comes from the combustion of the fuel. Substitution of material points to these two sources, because at the beginning we need less clinker, which also means less fuel. The fuel substitute, on the other hand, only reduces fuel emissions.

Companies differ in that they follow these two paths. Holcim is the market leader in the spare parts sector. 27% of alternative materials, including gypsum, used in cement in 2006, compared to around 10% in most other companies. , Heidelberg is the market leader in the use of alternative fuels. In 2006, around 16% of total consumption was derived from sources such as biomass, tires and plastics.

However, existing emission reduction methods are limited. In general, the material exchange can not be more than 75% of the total composition of the slag cement and 25% of the fly ash.

Companies also state that quality is a limiting factor for fly ash: they are often contaminated and must undergo additional treatment before being used in cement. According to Lafarge, the problem of fly ash quality will become more important in the future as "energy producers will have stronger emission limits", which means that fly ash will increasingly contain pollutants. , Italcementi also points out that many of its customers are willing to pay more for higher clinker contents, which limits the rate of replacement of materials.

|

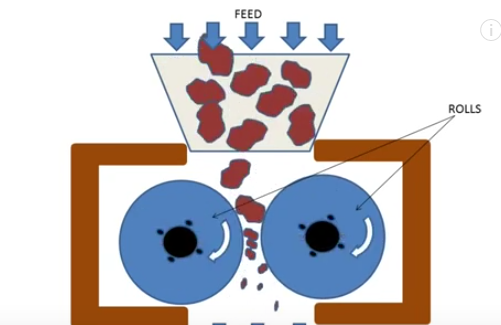

| The cement process uses a roll crusher |

But even this limited offer is threatened. Heidelberg reports, "new mills do not produce granulated blast furnace slag, they are not part of the process". Italcementi envisages a two-generation problem (considering the life cycle of a 50-year-old steelworks), where "the bulk of steel production is still produced by the traditional process, which unfortunately applies to emerging economies such as China and less and less in Europe or North America, where new technologies recycle scrap. "

The industry is also facing increasing competition for CO2-neutral fuels. The electricity sector is distorted by competition. This sector receives so-called green certificates to burn renewable biofuels. Italcementi emphasizes "a double punishment" for the electricity sector. Electricity producers can afford to pay a higher price for biofuels because they pass them on to the consumer. They receive credits for the use of renewable energies, which certify that the electricity generated is "carbon-free". But they can also benefit from the sale of surpluses resulting from EU ETS permits.

Respondents estimated the average carbon price in Phase II at 25 EUR / t or even 35 EUR / t. 30 euros per ton of carbon corresponds to a price increase of the finished cement by about 30%. However, many customers value the brand, Lafarge said, "they will not accept such a price increase." The company warns against a future scenario that would drive the industry out of Europe: "This could lead to a shift away from shifting demand to non-European countries." Suppliers. This is the challenge we are facing now. "

Cembureau points out that the EU ETS is inefficient because it focuses on reducing CO2 emissions in Europe: climate change is "a global problem" for which the ETS seeks to "find a European solution".

There is a fear that the system will limit production in Europe if the price of carbon in Phase II rises as expected. It could then be economical to import cement or clinker from outside the EU, which would be contrary to the very purpose of the EU ETS.

Many companies say that this is not their intention, but in the worst case they could be the only option. Cembureau believes that "it would be the worst solution". The irony is that total emissions will actually increase due to emissions caused by cement or clinker transport.

An obvious solution is to change the way the EU emissions trading system works for the European cement industry and to rethink Grandmother's approach. Lafarge believes that "this is not the way to calculate future allocations ... it is imperfect".

Cembureau, like most companies, is committed to a comparative approach around the world, not grandfather. This would establish a reference level for emission intensity based on best practices against which performance would be measured. Because benchmarking is performance-based, efficient operation is rewarded. This is the opposite of the approach of the grandfather, who can reward the most serious polluters and punish the "good" by granting permits from past activities.

Cembureau proposes "to combine the cement industry around the world to define a specific performance to be achieved per ton of product".

Every future plan must be clearly global. The Association supports a system that "covers the OECD and major developing countries, or protects countries that can reduce CO2 emissions through competitive distortions"

No comments:

Post a Comment